EN 469:2020

Protective clothing for firefighters - Performance requirements for protective clothing for firefighting activities

The EN 469:2020 standard specifies performance requirement levels for firefighters’ protective clothing. The standard's pictogram summarizes three key values: X (protection against flame and radiant heat), Y (water resistance of the product), and Z (breathability).

-

Flame (Xf)

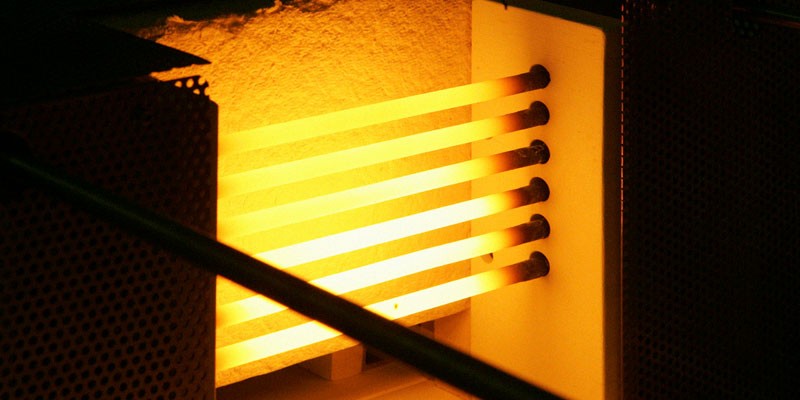

The EN ISO 9151 test method (flame test) involves heat transmission (flame) with a heat flux of 80 kW/m2.

Xf2 Xf1 HTI Heat Transfer Index Level 2 Level 1 HTI24 ≥ 13s ≥ 9s HTI24 - HTI12 ≥ 4s ≥ 3s Level 1 is the lowest level; level 2 is the highest level. -

Radiant heat (Xr1 or Xr2)

The transmission of heat (radiation) is tested in the EN 6942 test method. There is a heat flux of 40kW/m2.

Xr2 Xr1 RHTI Radiation HTI Level 2 Level 1 RHTI 24 ≥ 18s ≥ 10s RHTI 24 - RHTI 12 ≥ 4s ≥ 3s Just as for the previous test, level 1 is the lowest level, while level 2 is the highest one.More about the test method EN ISO 6942

-

Water tightness (Y1 or Y2)

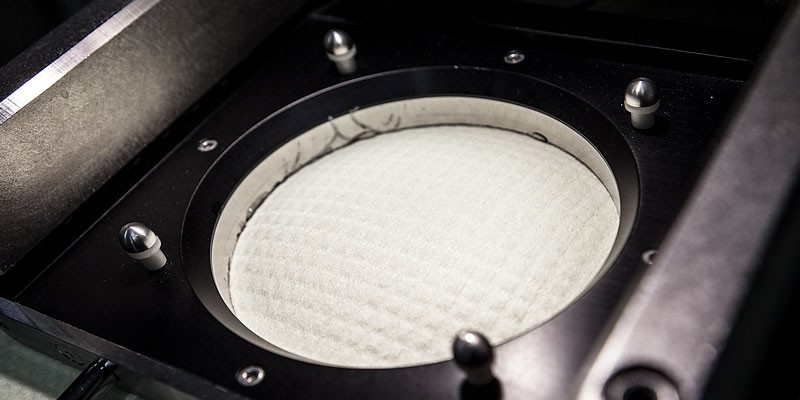

Waterproofness test EN 20811

- Y1 < 20 kPa

- Y2 ≥ 20 kPa

Y1: garments without membrane ; Y2: garments with membraneMore about the test method EN 20811

-

Breathability (Z1 or Z2)

More about the test method EN 31092Water vapour resistance EN 31092

Level Z1 > 30m² Pa/W.

Z1 indicates a higher water vapour resistance than Z2.

This garment is less breathable.Level Z2 ≤ 30 m² Pa/W

This garment has a lower water vapour resistance.

It is more breathable.

In addition the B annex of the EN 469 specifies the surface of the stripings (if the risk analysis demands them).

- B.1 The retroreflective material with single characteristic has to be fixed on the outer surface of the protective clothing with a minimum area of 0,13m2 for a circular visibility thanks to circular bands around the arms, the legs and the torso.

- B.2 In the case of the application of fluorescent non-retroreflective material or material with combined characteristics, the surface of the fluorescent material must be at least 0,2 m2.

The EN ISO 20471 standard can also be adopted.