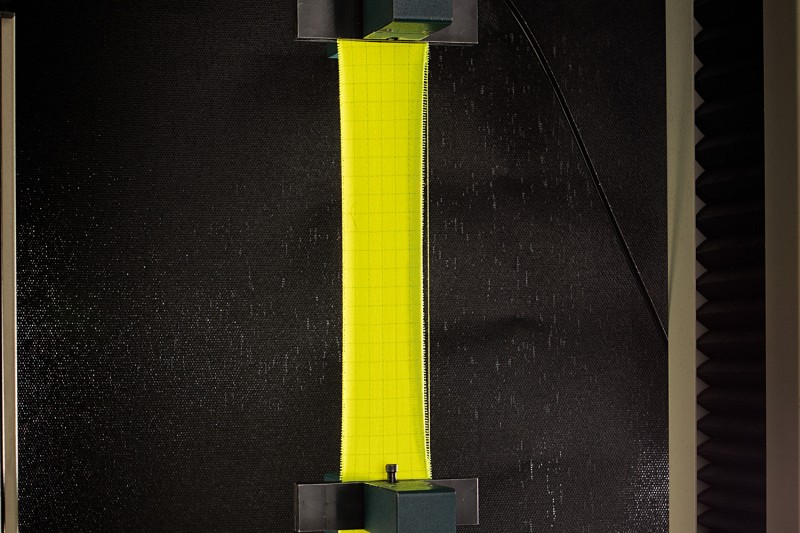

Limited flame spread

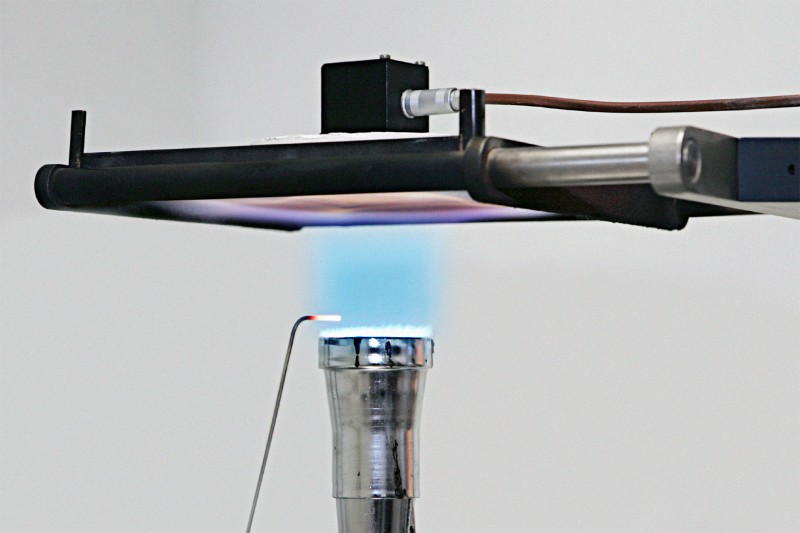

EN ISO 15025:2002

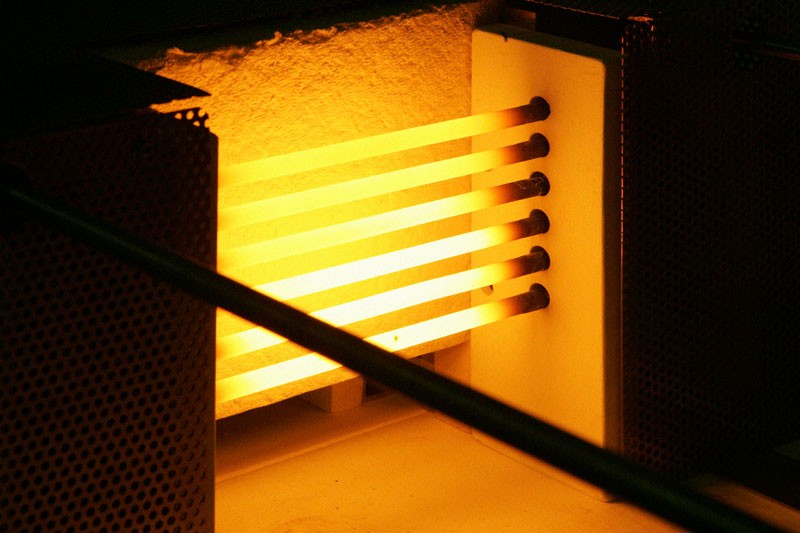

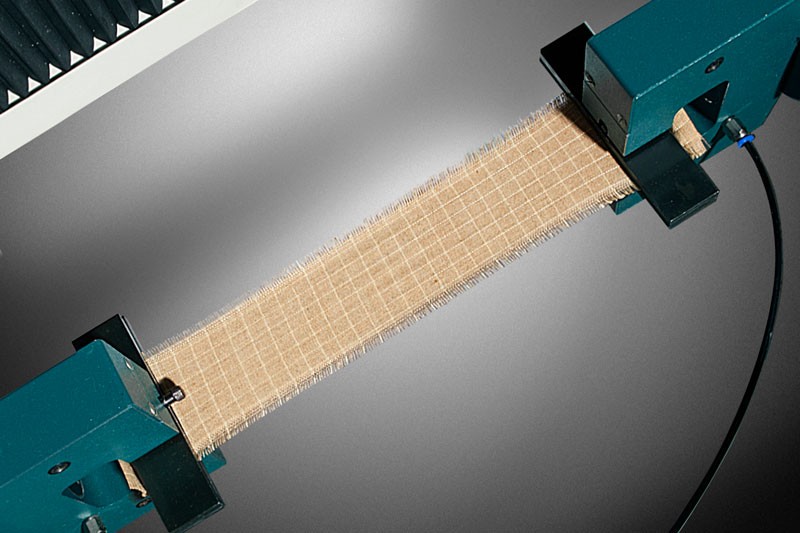

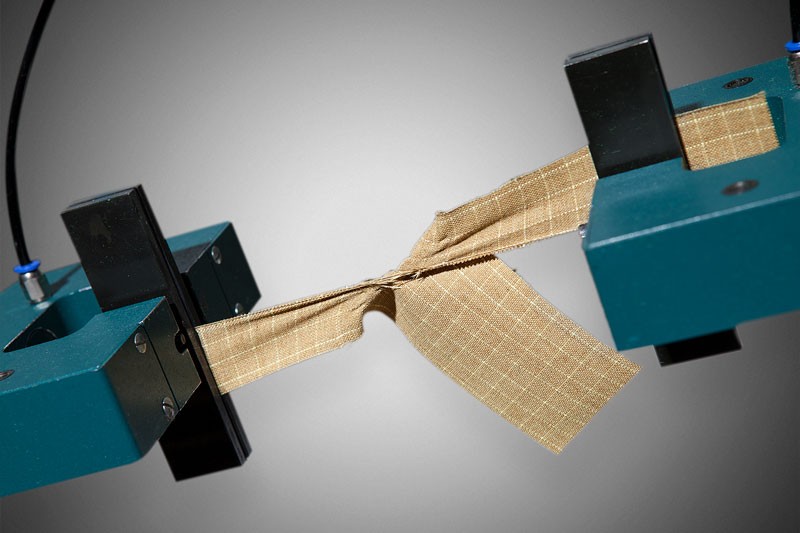

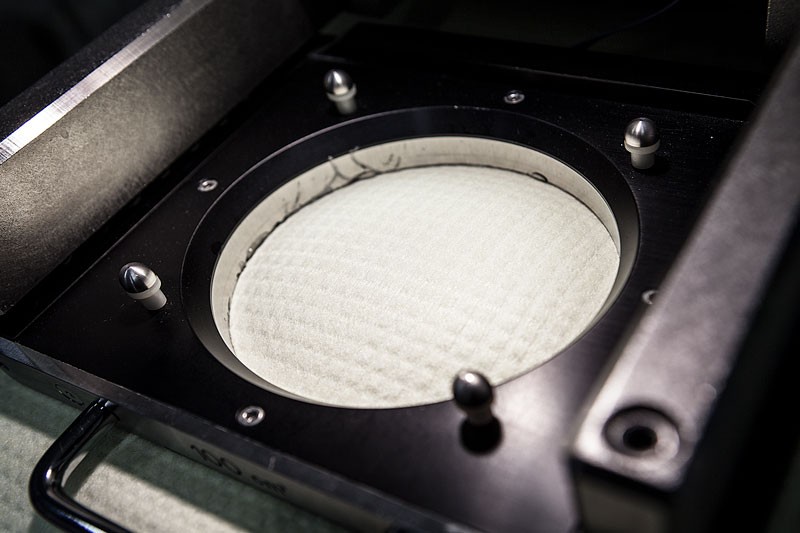

This test measures the limited spread of flames of vertically oriented textile fabrics (one or several layers), when subjected to a flame.

A defined flame is applied for 10 seconds to the surface of the fabric, whereupon one ascertains:

- whether the flame reaches the edge of the tested fabric

- how long the flame persists

- whether the incandescence spreads

- whether there are burning remains

- whether a hole is formed.