Exploring the market

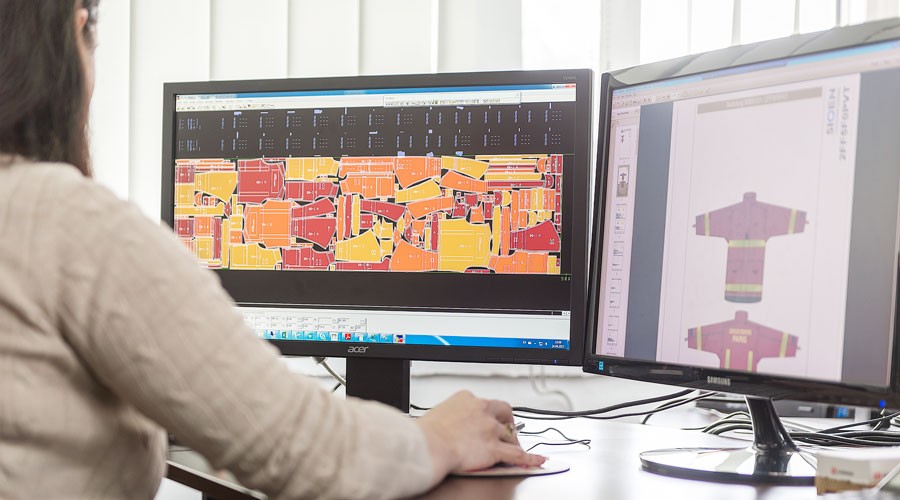

The process does not start with the tender itself. It starts a lot sooner. We constantly try to find out what our future customers are looking for. Are there any weak points in their current garments? Are there any improvements that they have in mind?

We expect more from our products than simply meeting the standards. We want them to be as comfortable as possible. No-one would buy just any type of car. You have special requirements in mind. It’s the same with firefighter suits.